Before Chinese New year break, during one of our Friday meetings with service, Ms.Psillides and Ms.Ware suggested if Raw Beauty would help produce gifts during this year’s Foundation event. This event is about showing UWCSEA’s gratitude to members of the community who have helped fund many of the environmental initiatives and sustainable processes here on campus.

This year, they suggested that we could produce a soap that had a connection to our sustainability as a campus. My chair and I were thrilled at the idea of Raw beauty being a part of its first event. The only issue was that they needed these soaps by the end of February. With CNY break, we only had 2 sessions to make it, and we had a few grade 9’s joining that first week who didn’t know how to make soaps, and our grade 10’s had left for their mock exams.

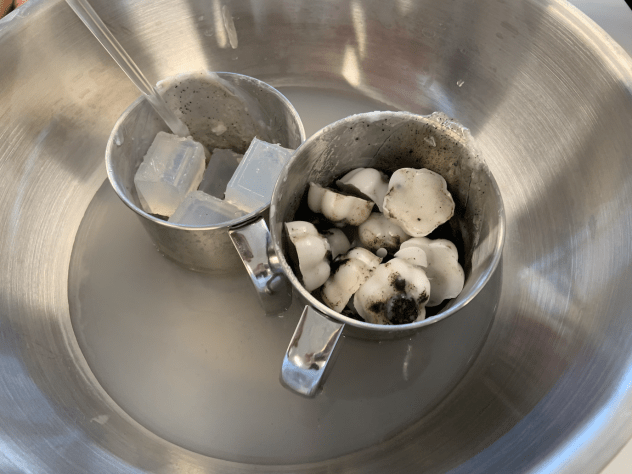

But regardless, we agreed and decided to do as best as we could to meet the requirement of 200 soaps, with the assumption that we would have to come in during lunchtime to meet that goal. In terms of having our product connect to our campus, during one of our meetings, we had an idea of using recycled coffee grounds from campus, and incorporating them into the soap mixture, where they had exfoliation benefits and a relaxing scent. Because this was a last-minute ordeal, we went along with this. Santai (our school cafe) gave me a bag full of coffee grounds, which I took upstairs and we added the grounds to our melt-and-pour mixture before pouring it into the molds. This was an example of how we were actively engaged with our cause as an environmental initiative by recycling materials. We were aware that we wanted to avoid participating in the cycle of waste generation and pollution, so incorporating these coffee grounds were a great way of doing so. (LO7)

(Referring to the photo above) As we were making these type of soaps for the first time, we experimented by putting the coffee grounds at the top and then pouring the soap. We realised that we didn’t like the appearance of these soaps, but the benefit of soap-making is that nothing goes to waste. If the products don’t come out as expected, they can simply be melted and re-molded again. This way, it is a zero-waste process.

As mentioned previously, our expectation was to meet 100, at best. But with efficient collaboration and smart communication across the group, we ended up making 202 soaps in just 1.5 hours. (LO5) I think that this situation was entirely dependent on how we as a team worked together for that one session. We started off by giving the grade 9’s a brief introduction as to our agenda, and then got started right away. We divided into 4 groups, kept the soap molds ready, and Ms.Giddins was kind enough to arrange the ice baths and melting stations ahead of the session, and her contribution really helped us get started on a productive note. Some people took the role of melting, while the chair and I were in charge of adding the right amount of coffee to the mixture to avoid it becoming too dark/grainy. We would immediately de-mold the soaps once it solidified so that other groups could pour their melted mixture. In the end, we not only met our end goal, but learnt how to work better as a team and exposed ourselves to a new recipe that we can use again in the future.

The grade 9’s, who were new to our service, were extremely efficient and collaborative, despite knowing very little about the soap-making process, but they caught up very quickly with the guidance of the grade 11’s. In general, I’m very proud of the achievement we all did and the fact that we took up this responsibility despite the challenges it came with. (LO2)

This makes me optimistic towards Raw beauty’s future as a service, and although we aren’t making a profit on these coffee soaps, I still feel like it enhanced our cause as an environmental initiative and brought our service closer together.

Below are some photos of how it went:

Above are all the soaps we made