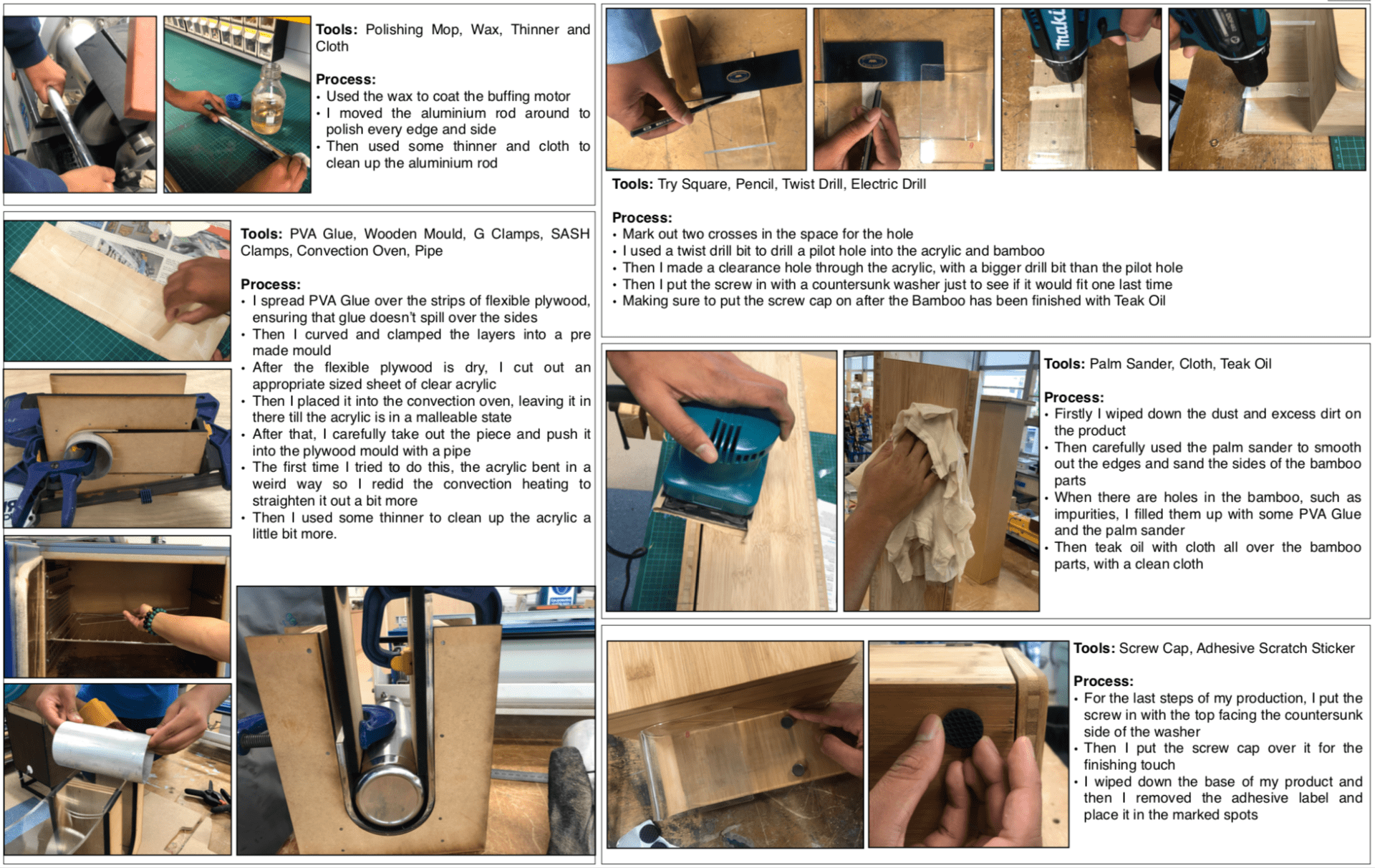

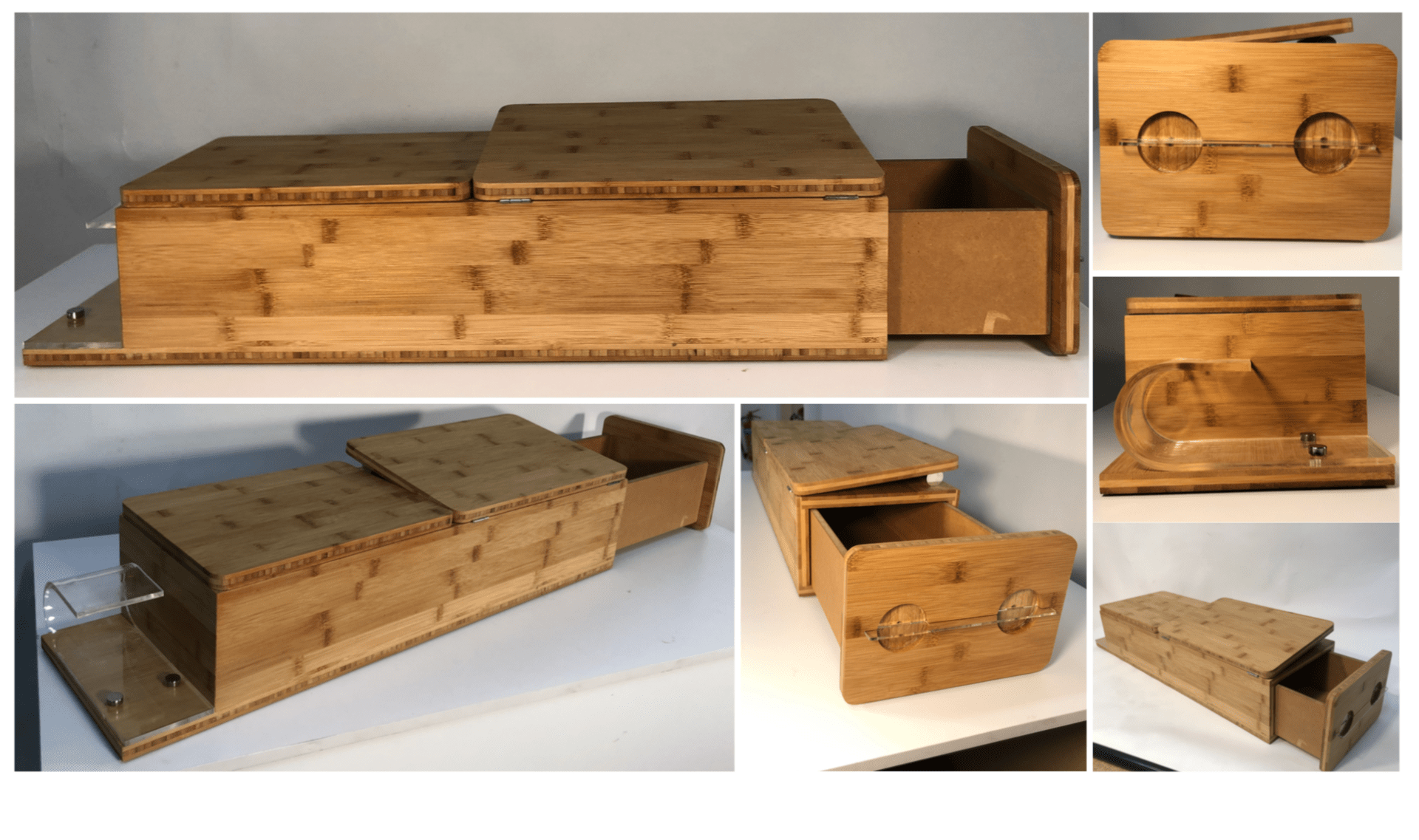

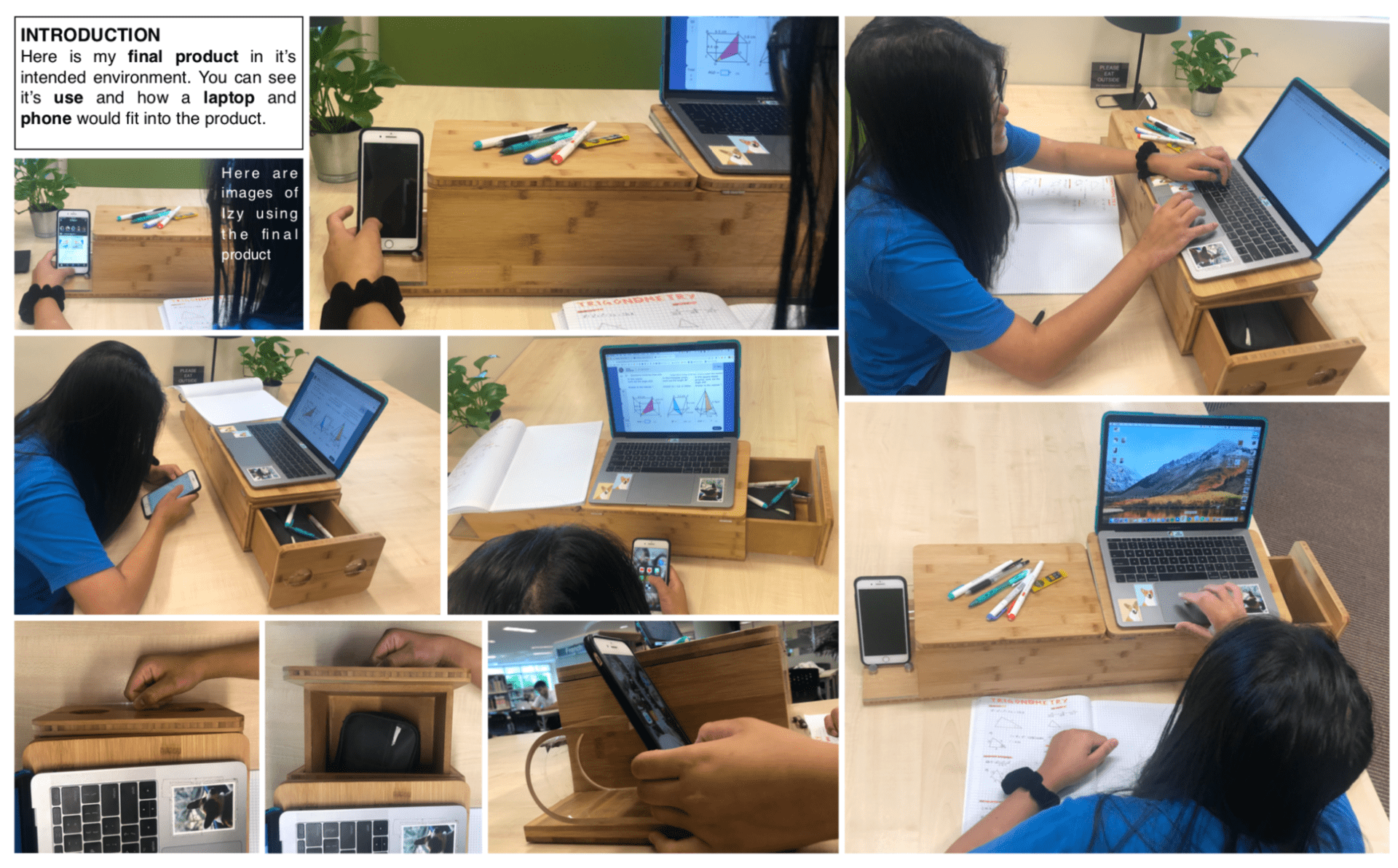

In this part of the process, I was working turning my planning and designs into a real manufactured product. This allowed me to critically asses my work, and I was able to learn more about the obstacles facing designs and manufacturers, and how to work around them. Below are the photos of my realization process.

This was a really interesting post to read! Your coursework looks very organised and appealing to read. During my project, I found it difficult when transferring the organic shape of my housing to the Adobe Illustrator for CNC Milling given that some of the measurements were vague. However, you had a good idea in using a large-diameter aluminium rod to curve the acrylic sheet as per your wish.

Also, I noticed that you used a thin aluminium rod to create the lift in the laptop stand, but I was wondering if you considered making it adjustable based on the physique of the user?

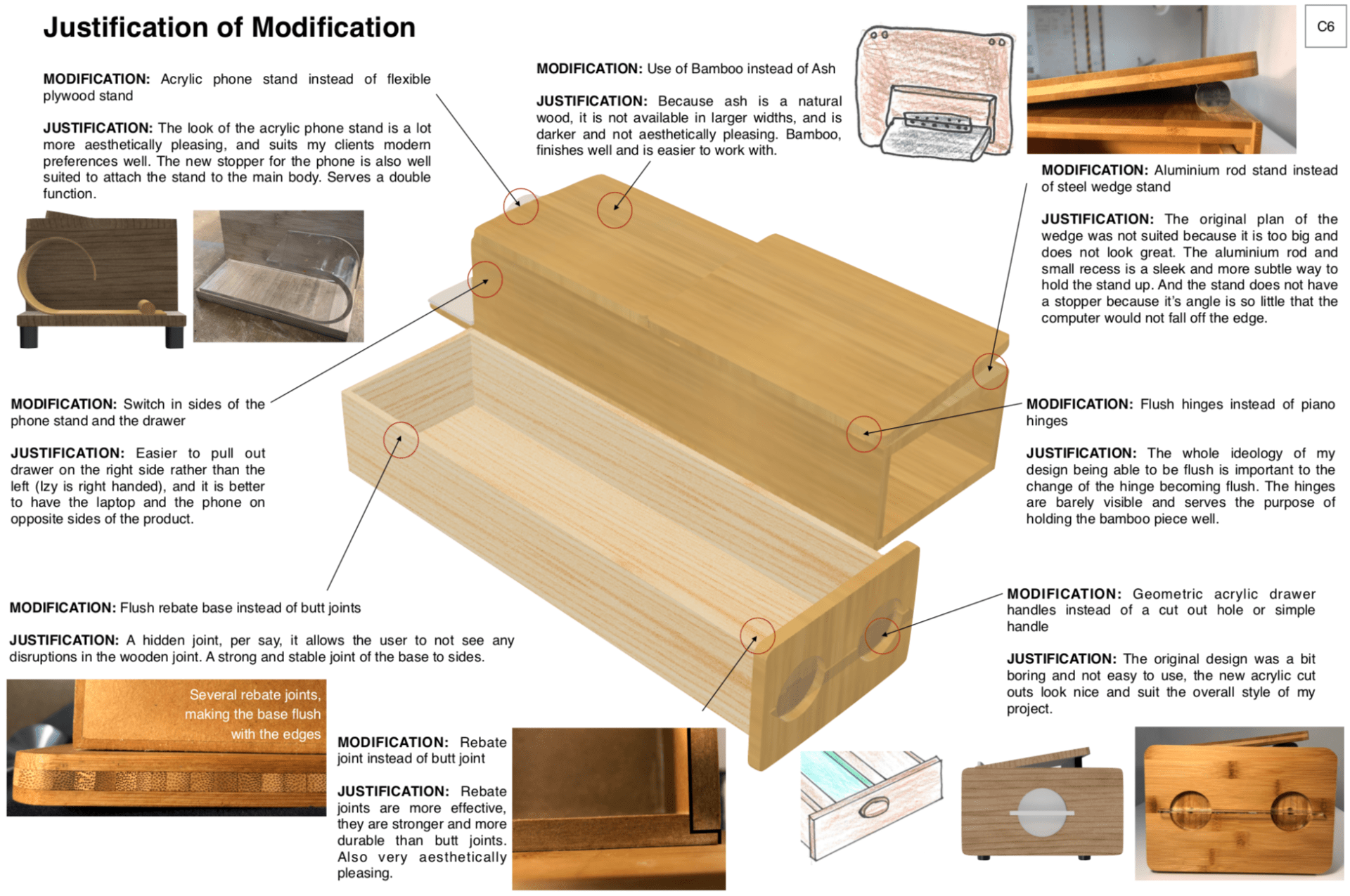

Thank you! So originally I was planning on having the laptop stand to be adjustable. However, while I was producing my design, I came across some difficulties and had to make adjustments accordingly. Ultimately, I decided on using an aluminum rod because I found the angle to be just right so it doesn’t require and stopper, sleek, and able to be removed so the top can be flush.